|

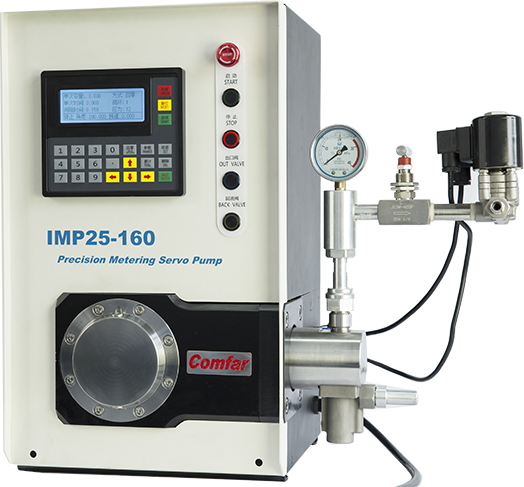

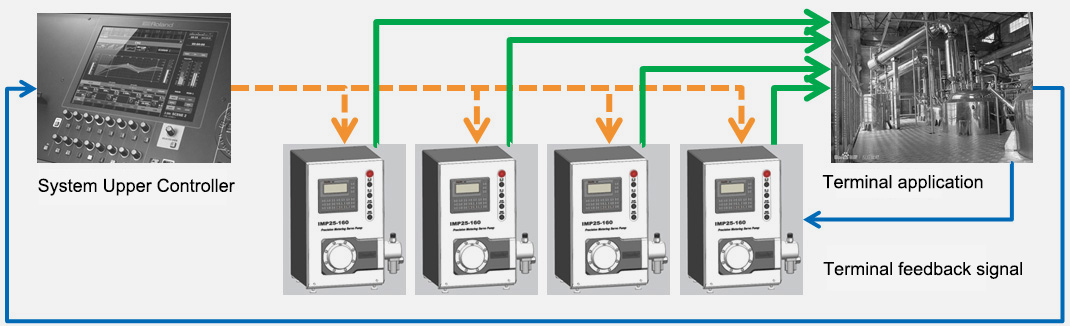

SMP(Smart Metering Pump) series intelligent servo metering pumps are specially developed for complex process flow and harsh liquid pumping accuracy, which can help you to achieve accurate feeding under high pressure and high temperature conditions, and multi-pump centralized control can achieve high-precision proportioning. It is widely used in many industrial fields such as chemical industry, food industry, pharmaceutical industry, water treatment, new energy, and special processing, and belongs to general equipment. |

|

Flow accuracy:+/-2 ‰ Note: The nominal flow accuracy is the measured value with clear water as medium at 20 C. |

|

|

1. The pump body is driven by AC servo motor, and the main components are modularized. 2. The self-developed control system can directly set various pumping parameters, realize automatic operation and meet the complex requirements of various working conditions. 3. Convenient calibration method can correct output error in time. 4. I/O signal interface of automatic alarm function, such as reservation, can be configured according to specific application. 5. Configuration of 485 communication interface can realize remote control of pump, transmission of control parameters, logic control signals, and so on, and then realize intelligent operation of network. |

|

Standard function of servo metering pump numerical control system: |

Selection function: |

|

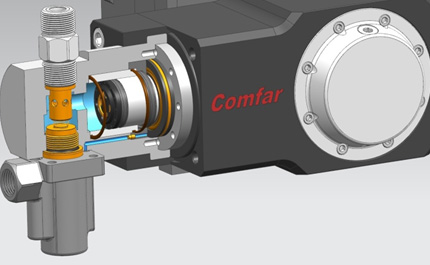

| 1. The pump body is driven by AC servo motor, and the main components are modularized. 2. The newly designed integral drive unit has the characteristics of high rigidity and wear resistance, which ensures the high reliability of the whole machine. 3. The multi-channel combined seal structure completely isolates the mutual pollution between lubricant and working medium, and is suitable for all kinds of corrosive media and hygienic occasions. 4. The newly designed precision inlet and outlet valves and fluid passages can withstand high loads. 5. Long-life seal design and unique built-in leakage and return channel can prevent the leakage of medium in case of seal failure and reduce the risk of environmental accidents. 6. Explosion-proof design can be provided according to customer's requirements. |

|